|

|

|

|

SERVICE Laser cutting for sheet metalsIn addition, to disc and format saws, we offer laser cutting for sheet metals. This is our competitive advantage. The technology of cutting is precise and fast with minimal waste. It allows to produce components with high demands for quality. After laser cutting, we offer straightening, sandblasting, deburring of components or grinding.

|

|

|

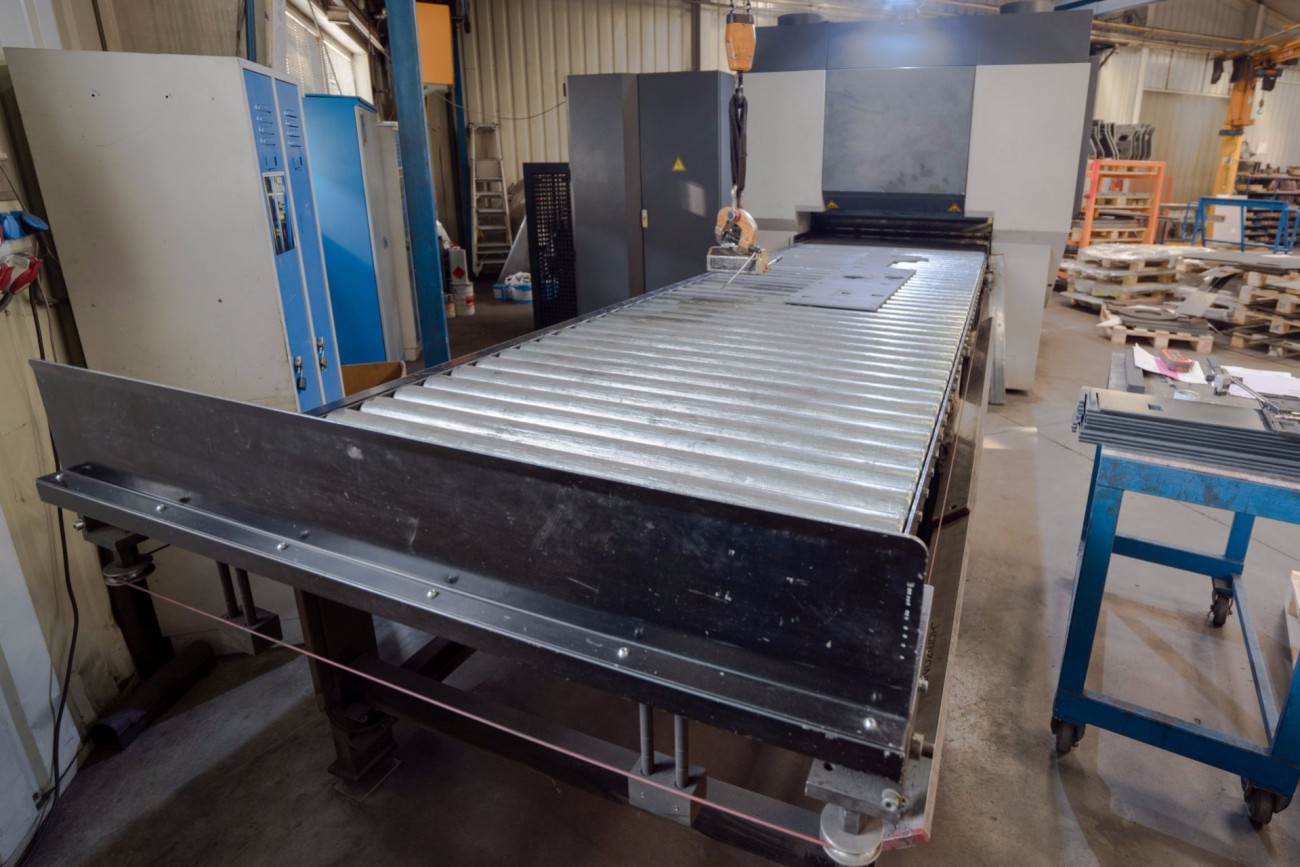

SERVICE Sheet metal straighteningManual straightening is time-consuming. When our straightening rollers are used, the process is done in a few minutes and almost without tension. In addition, we deliver excellent results in straightening parts with spaces gaps using the built-in gap regulation. We offer high quality, precision straightening for sheet metals with straightening machines.

|

|

|

SERVICE Sheet metal bendingCNC technology is used for bending and folding of steel sheet. This technology optimizes the bending and folding processes and guarantees the bend angle accuracy up to 0.01 degree. We offer bending in complex bend shapes and removing traces on soft metals on which tools leave a visible trace during bending.

|

|

|

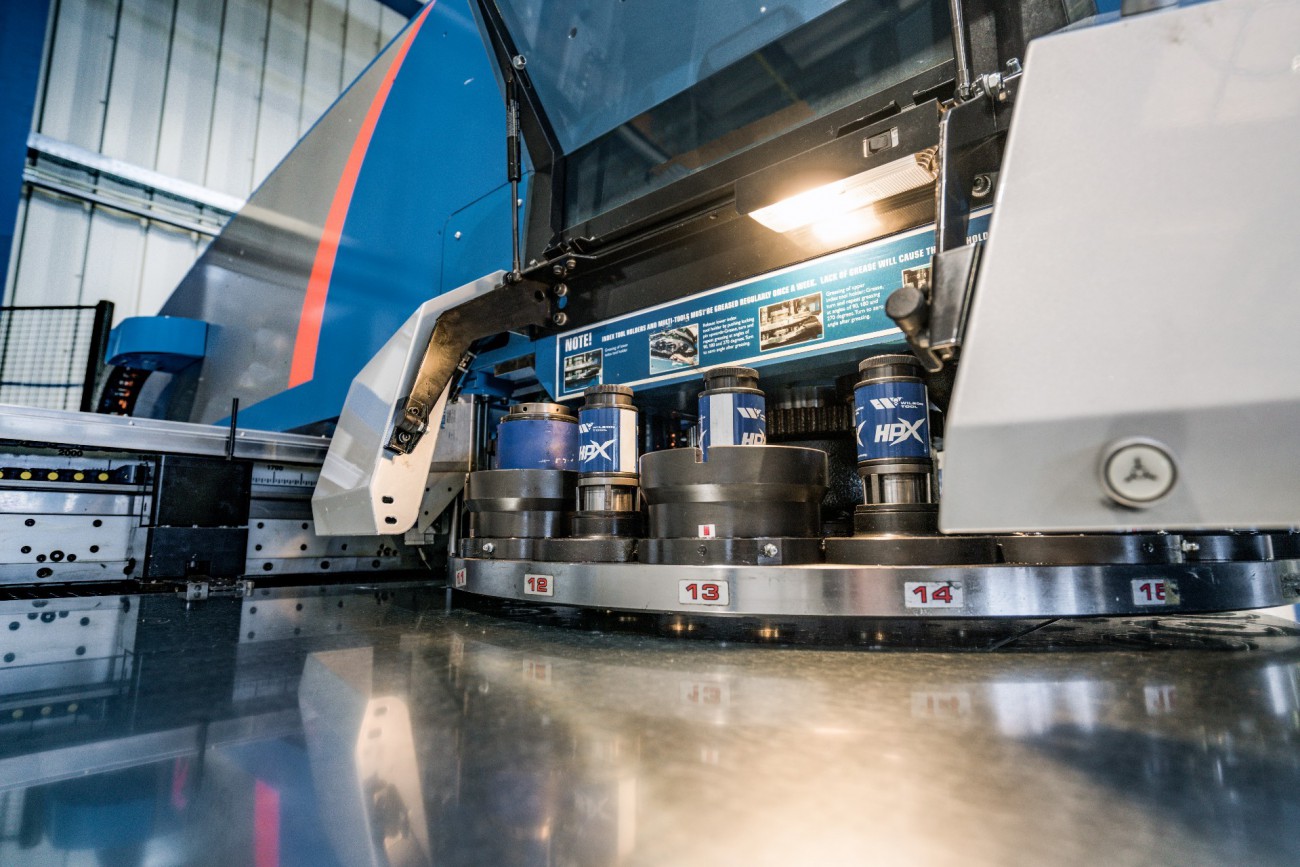

SERVICE Sheet metal punchingWith punching technology, we cut shapes, holes and press sheet metal into different shapes. We process simple and complex die cut shapes. Punching tools rotate materials to different positions. Advance in punching is that the technology is fully automated. During the process the material and its surface is not damaged or scratched.

|

|

Questions?