|

The usage of state of art technology and robotic workplace

We use welding equipment such as semiautomatic welding machines, welding inventors, pneumatic spot welders and welding machines.

|

MIG/MAG

|

Welding

|

Questions?

|

METHODS MIG (CO2 welding)MIG is one of the most popular method for welding. The weld joints arise during arc welding, which occurs between continuously fed welding wire and weldment. The welder moves the welding wire smoothly, in meantime, welding wire is automatically fed to arc zone, melts, and generates welding metal.

Advantages of MIG welding:

Disadvantages of MIG welding:

|

|

|

METHODS MAG welding methodMAG works in a protective atmosphere or within active gas (e.g. carbon, dioxide, a mixture or argon, carbon dioxide, or argon and oxygen). It is a semi-automatic welding method. The shielding gas used during welding process is the only difference between MAG and MIG welding. In addition, active shielding gas prevents entering the air to molten metal and participates in the chemical processes, which take place in the molten weld metal. Choosing the right metal inert gas welding is our priority number one. We have skilled welders, who have a lot of experience with MAG/TIG/MIG welding.

|

|

|

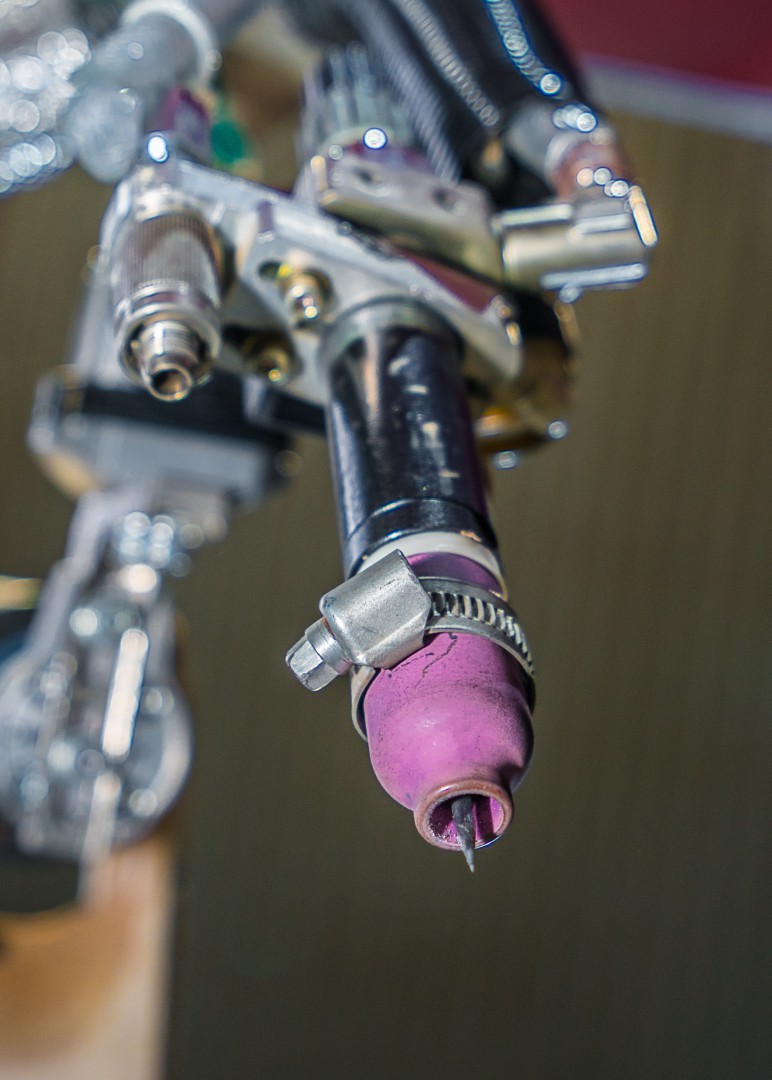

METHODS TIG welding methodTIG is one of the most complex and versatile welding methods. TIG welding is a process that enables top-quality welds. The welder holds welding torch to create an electric arc and manually adds material. The weld joins together (metal parts) by heating the surfaces to the point of melting with an electric arc, and uniting them by pressing.

Advantages of TIG welding:

Disadvantages of TIG welding:

|

|

|

Stainless steel |

|

|---|---|

| Robot for MIG/MAG and TIG | 1x positioner |

| Workplace up to 1 500 kg | dimension of weld 1 500 x 1 500 x 1 500 mm |

|

ST welding |

|

|---|---|

| Robot for MIG/MAG | 2x positioner |

| Robot for MIG/MAG | 1x positioner |

| Workplace up to 300 kg | dimension of weld 1 200 x 1 200 x 1 200 mm |

| Workplace up to 1 500 kg | dimension of weld 1 500 x 2 100 x 1 000 mm |

| Workplace up to 4 000 kg | dimension of weld 3 000 x 4 000 x 2 000 mm |

back to mechanical manufacturing