|

HIGH QUALITY RESULT We offer cutouts for serial production

|

|

|

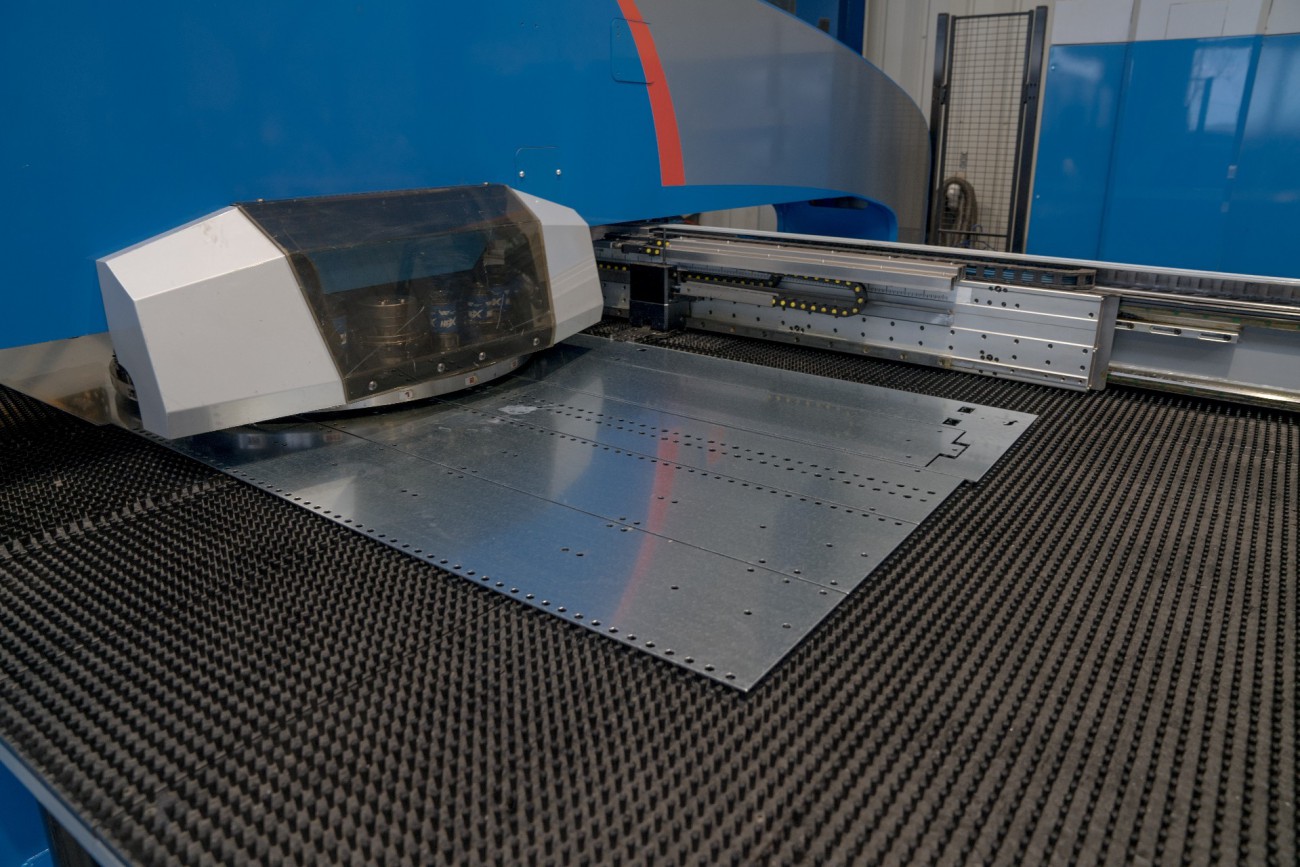

DIFFERENT WEIGHTS PARTS Cutouts up to maximum sheet weight of 200 kgModern punching technology offers a choice of processing options: punching and forming simple and complex parts up to 200 kg of the sheet weight, in small or large series, and from different materials. The process is automated, the waste is kept to a minimum, this saves money in the long run as no materials will be thrown away. The punching technology makes holes in sheet metal in any shapes and the presses various shapes into sheet metal parts.

|

|

|

Complete

|

Automated

|

High quality

|

No punching

|

|

ASPECTS OF TECHNOLOGICAL APPROACH A view on innovative, modern sheet metal punching technologies at IMC Slovakia s.r.o.Industrial punching machines are fast, efficient automated devices, and thus the production is more economic. The punching machinery allows automated mechanical operations, which ensure that material surfaces are not scratched or damaged during a punching process.

|

|

|

SPECIFICATIONS Technical specification of sheet metal punching

|

|

back to sheet metal processing