|

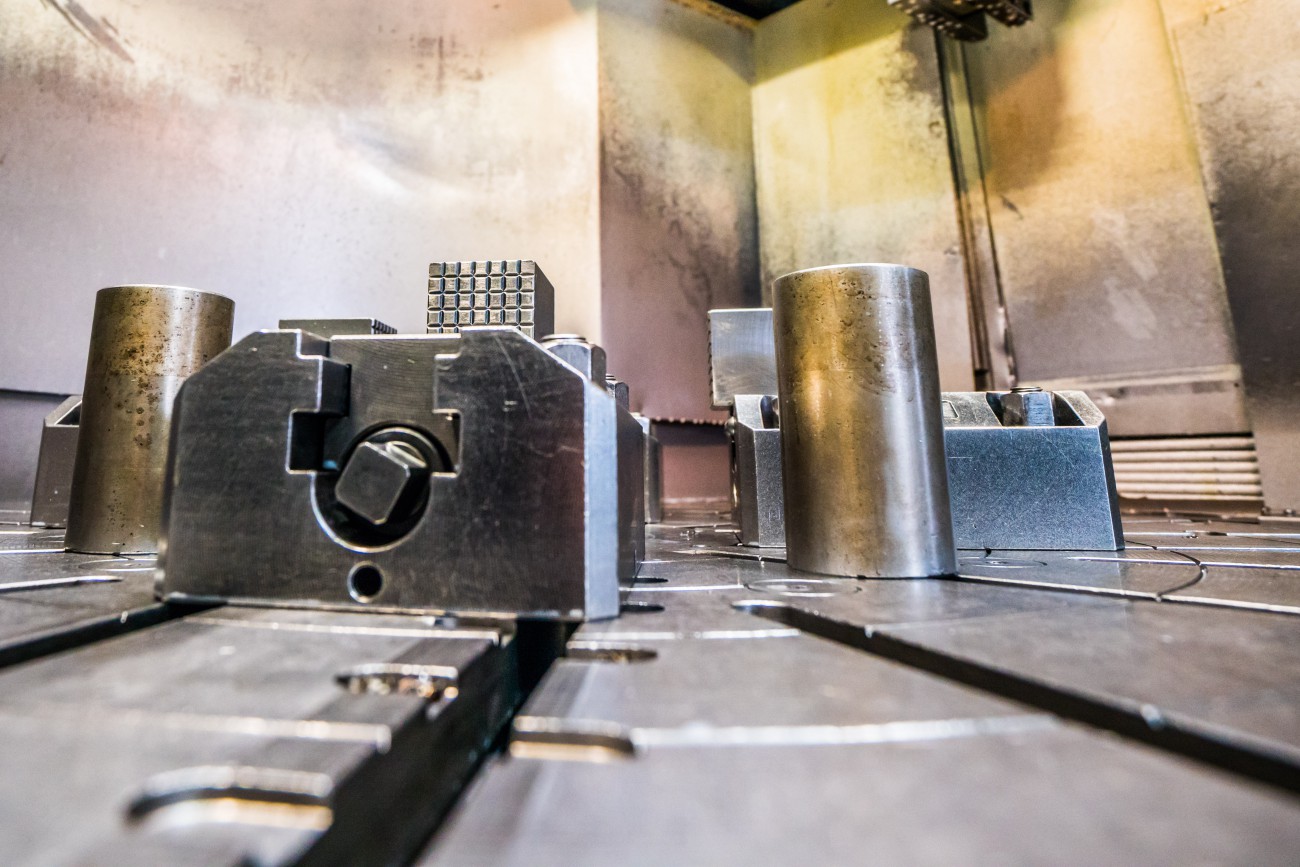

QUALITY RESULTS Quality lathing for external and internal surfacesThe manufacturing engineering program of the IMC Slovakia, company includes lathing as an important part along with the machining of external and internal cylindrical surfaces. Lathing technology is used for machining the cylindrical shape of metal parts, components or pieces.

|

|

|

QUALITY EQUIPMENT We use CNC and Conventional lathesWe use conventional lathes for simple parts. For parts with the highest degree of accuracy and quality, we use CNC lathes with accuracy of 0.01 mm.

|

|

|

Accuracy

The accuracy of production is our number one priority.

|

Technique accuracy

We use CNC and Conventional lathe machines.

|

Top quality employees

Lathing technology performs by highly skilled employees. |

|

ASPECTS OF TECHNOLOGICAL APPROACH A view on innovative, modern lathing technologies at IMC Slovakia s.r.o.Technological approach depends on what type of product customers need to process. We use conventional lathes for simple parts, which have more dimensional and deviation tolerance. To achieve the highest degree of accuracy and surface quality in machining and mass production, we use our own CNC machinery and lathes.

|

|

|

SPECIFICTIONS Technical specification of metal lathing process

|

|